There are a variety of ways to package your product in pulp. When you think of molded pulp what do you think of? Perhaps you think of paper first, however, pulp can be manufactured into containers that can keep your products safe and be sustainable. First you would need to think about where the pulp is coming from. What is the pulp source? We are seeing more and more pulp products in the marketplace where it hasn’t been before. This not only is a positive environmental consciousness that has gained momentum but also a global commercial opportunity. Pulp products and packaging in pulp have gone from a single bowl at a local salad bar to becoming the source for high-end retail products. Big commercial businesses and Fortune 500 companies are steadily moving forward with their social responsibility models. It’s like a breathe of fresh air to know that products are being packaged in cellulose materials that are biodegradable, compostable and sustainable.

There are a variety of ways to package your product in pulp. When you think of molded pulp what do you think of? Perhaps you think of paper first, however, pulp can be manufactured into containers that can keep your products safe and be sustainable. First you would need to think about where the pulp is coming from. What is the pulp source? We are seeing more and more pulp products in the marketplace where it hasn’t been before. This not only is a positive environmental consciousness that has gained momentum but also a global commercial opportunity. Pulp products and packaging in pulp have gone from a single bowl at a local salad bar to becoming the source for high-end retail products. Big commercial businesses and Fortune 500 companies are steadily moving forward with their social responsibility models. It’s like a breathe of fresh air to know that products are being packaged in cellulose materials that are biodegradable, compostable and sustainable.

Pulp Fiber Sources

Pulp fibers can be derived from many different sources. It can come from corn, sugarcane, bamboo, wood, grass and other fiber crops. The cellulose fibers are separated from the source and processed into a slurry. Different pulp fibers have different tolerances and texture. Virgin fibers are stronger then recycled fibers and have a longer term for recyclability. Also, there are some crops such as bamboo that are stronger then some wood fibers and are a fast growing crop which makes it a sustainable solution for pulp.

Can Pulp be Coated?

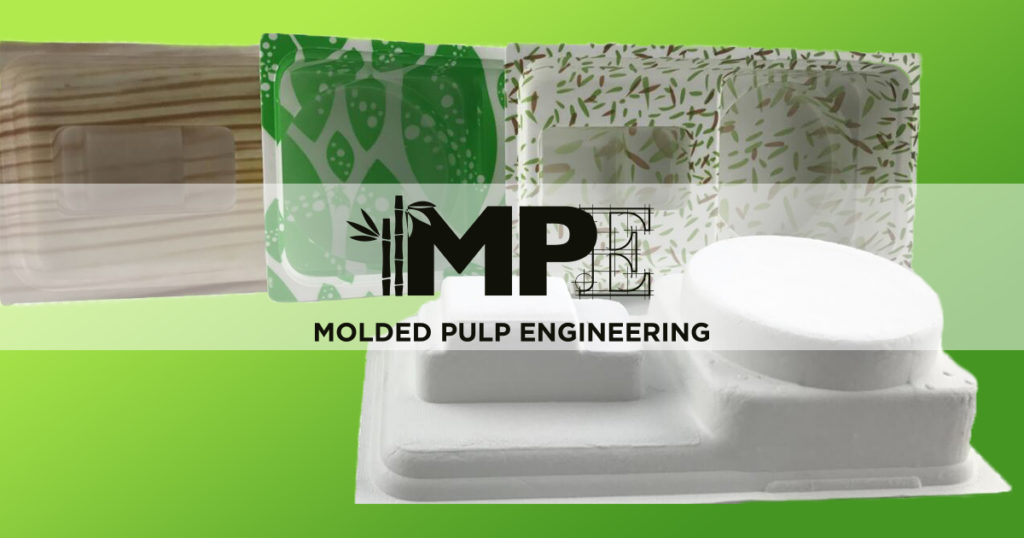

Pulp containers are showing up in a multitude of industries. I’ve seen them at local farm markets holding fruit and vegetables in place, hotel breakfast stations, deli’s and in the retail marketplace. Pulp can be coated or laminated in order to either have color or to be able to hold up against oven temperatures, hot and cold liquid, sauces and even clinical formulas such as hydrogen peroxide or iodine. This is a type 4 pulp product, FAQ , or a pulp product that has had something added to it such as a laminate. There are an array of laminates that can be used and MPE also has proprietary coatings to apply to pulp. A type 4 product can add value because of its added tolerance. I have even heard of flower seeds being added to pulp and then the product directions asks the consumer to bury the container in their garden to produce flowers later on. A very clever idea. Although pulp can be colored, just like make-up, sometimes its natural beauty is best.

Renewable Packaging & Product Innovation